Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

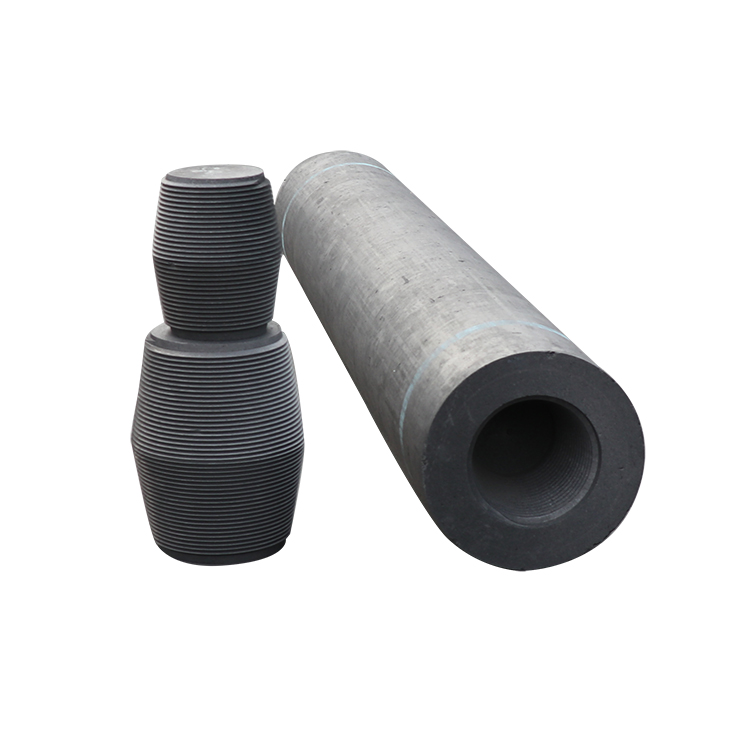

(1) Graphite electrode nipples can be used in electric arc steelmaking furnaces. Electric furnace steelmaking is a major user of graphite electrodes. Electric furnace steel production in some areas accounts for about 18% of crude steel production, and graphite electrodes for steelmaking account for 70% to 80% of the total amount of graphite electrodes. Electric furnace steelmaking is to use graphite electrodes to introduce current into the furnace and uses the high-temperature heat source generated by the arc between the electrode end and the charge to smelt.

(2) Graphite electrode nipples can be used for submerged electric furnaces. The submerged electric furnace is mainly used for the production of industrial silicon and yellow phosphorus. Graphite electrodes are required for submerged thermal electric furnaces with high density. For example, each 1 t of silicon needs to consume about 100 kg of graphite electrodes, and each 1 t of yellow phosphorus needs to consume about 40 kg of graphite electrodes.

(3) Graphite electrode nipples can be used in resistance furnaces. The graphitization furnace for the production of graphite products, the furnace for melting glass, and the electric furnace for the production of silicon carbide are all resistance furnaces. The materials in the furnace are both heating resistors and objects to be heated. Usually, the conductive graphite electrodes are embedded at the end of the resistance furnace. In the furnace head wall of the upper part, the graphite electrodes used here are not continuously consumed.

(4) Graphite electrode nipples can be used to prepare special-shaped graphite products. The blanks of graphite electrodes are also used for processing into various shaped graphite products such as crucibles, molds, boats, and heating elements. For example, in the quartz glass industry, 10t of graphite electrode blanks are required to produce 1t of electrofusion tubes; 100kg of graphite electrode blanks are required to produce 1t of quartz bricks.

Through the above introduction and analysis of the Application of Graphite electrode nipples, hope it helps you.

Here are some specific applications of graphite electrode nipples:

Electric arc furnaces (EAFs): Graphite electrode nipples are used as the primary conductive material in EAFs. They are connected to the power supply and provide the electrical energy necessary to generate the high temperatures required to melt the scrap metal and additives for steel production.

Ladle furnaces: Graphite nipple electrodes can also be used in ladle furnaces, which are used for secondary steelmaking, refining, and alloying. They are immersed in the molten steel to further refine the composition and temperature of the steel before casting.

High-power applications: Graphite electrode nipples are preferred for high-power applications due to their high electrical conductivity and thermal resistance. They can withstand extremely high temperatures and carry large amounts of electrical current, making them suitable for demanding steelmaking processes.

Continuous casting: Graphite nipple electrodes are also utilized in continuous casting machines, where they help maintain the desired temperature and composition of the molten steel during the casting process.

Foundries: Graphite electrodes are also used in foundries to produce cast iron and other metal alloys. They are inserted into the molds to provide electrical resistance heating, aiding in the melting and shaping of the metals.

Recent Posts

undefined

Quote Now

Quote Now