How to choose petroleum coke carburizer?

For cast steel or electric furnace smelting in the casting industry, the core of carburizing technology is the use of low sulfur, low nitrogen, high porosity carburizing agent. Petroleum coking carburizer main producing areas of Liaoning, Tianjin, Shandong and other places. Among them, Liaohe Oi...

What material is the carburizer made of?

Want to understand what carburizing agent is material, to start from the upstream carburizing agent raw material link. At present, the most widely used carburizing agent in the market is calcined petroleum coke carburizing agent and graphitized carburizing agent. 1. Calcined petroleum coke carbu...

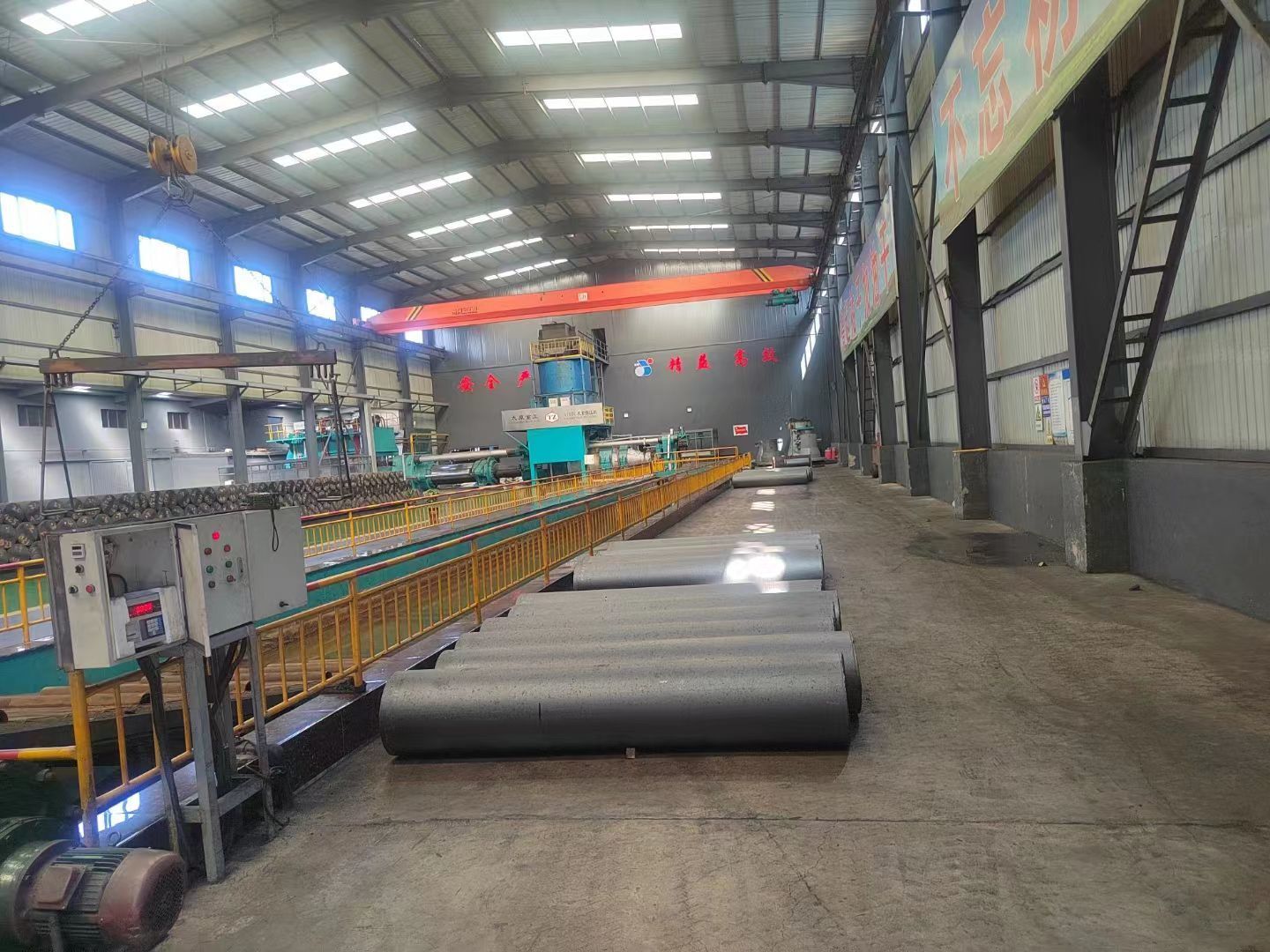

Application field of graphite electrode

Graphite used as electrode, brush, carbon rod, carbon tube, mercury rectifier positive electrode, graphite gasket, telephone accessories, TV picture tube coating and other widely used in the electrical industry. Graphite electrode is the most widely used, in the use of graphite electrode smelting...

Industrial production how to buy carburizing agent?

Carburizer is not the higher the price will be better, its quality is restricted by many factors, such as fixed carbon content, sulfur content, water content, volatile components. It also has a great relationship with the characteristics of the products, the methods used in the process of use and...

The ultimate solution to graphite electrode breaking

In view of the fracture problems caused by operation reasons, control reasons and electrode quality reasons of graphite electrode in steelmaking, we make the following preventive measures and operational suggestions. First, if the fracture is caused by smelting operation, we can do the following ...

The purpose of raw material calcination in petroleum coke calcination process

In the graphite electrode for steel making or anode paste for aluminum and magnesium making (melting electrode), in order to make petroleum coke (coke) meet the requirements, the coke is calcined. Calcination temperature, petroleum coke volatiles are considered factors. (1) Remove moisture a...

How to choose graphite electrode material correctly

We all know that graphite has other metal materials can not replace the high quality characteristics, as the preferred material, graphite electrode material in the actual selection of materials often have a lot of confusing characteristics, the selection of graphite electrode material is also a l...

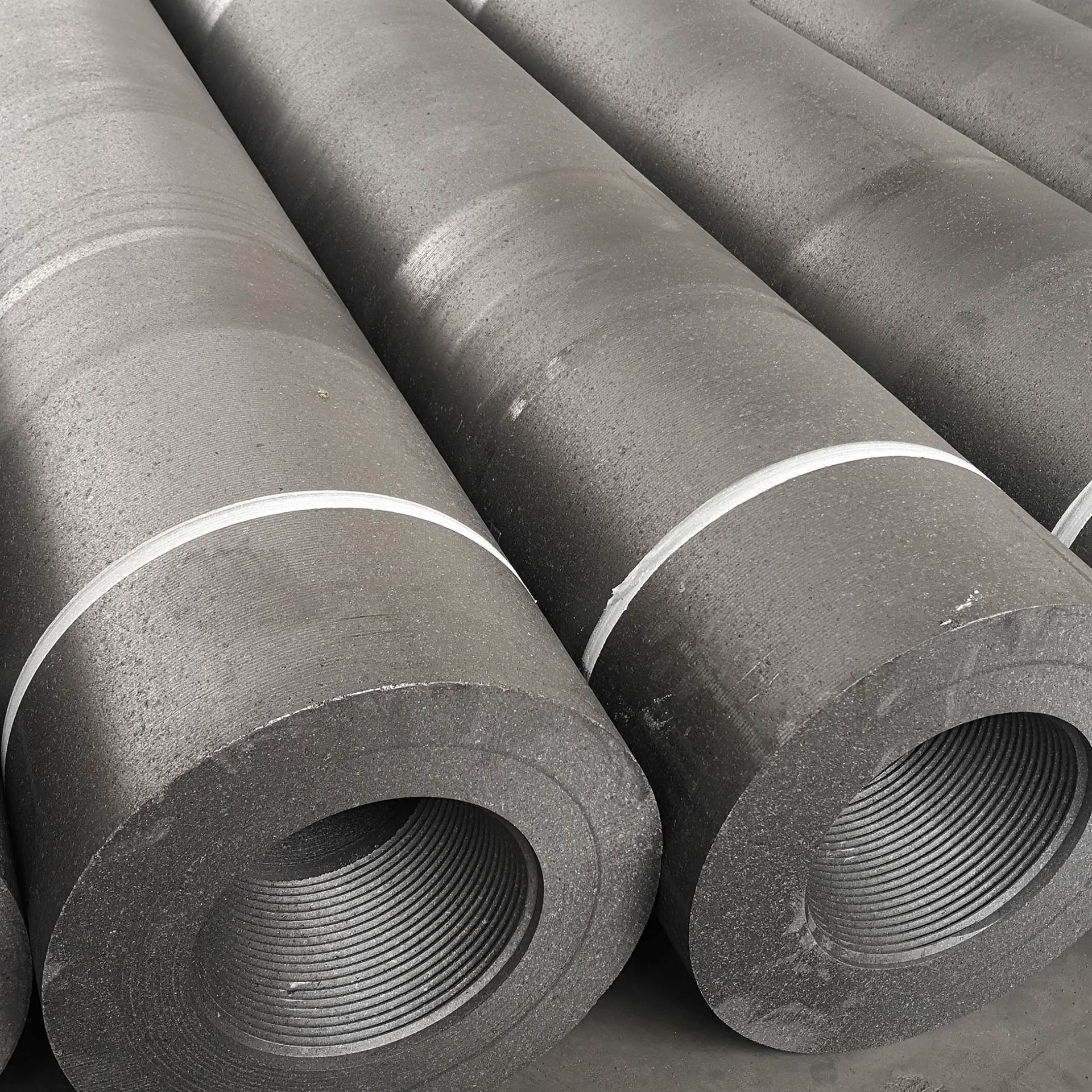

Processing of graphite electrode details

We need to know that the first wet graphite electrode should be dried before use, and check whether the thread inside the electrode hole is complete. When we use compressed air to clean the spare graphite electrode surface and hole internal thread, there shall be no oil or water; Avoid cleaning w...

The main factors affecting the absorption rate of carburant

1, the influence of carburizing agent particle size The use of carburizing agent carburizing process includes dissolution diffusion process and oxidation loss process, carburizing agent of different particle size, dissolution diffusion rate and oxidation loss rate is different, and carburizing ag...

Quote Now

Quote Now