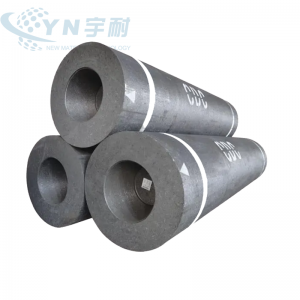

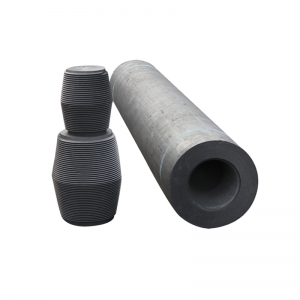

HP Graphite electrode

Cov txheej txheem ntawm graphite electrodes feem ntau suav nrog: raw khoom (wool) → batching → kneading → extrusion molding → kub sintering (1550 ~ 1700 ° C) + kev kho cua sov (1100 ~ 1200 ° C) + xov.

1. Wool pretreatment: tshem tawm cov impurities hauv cov ntaub plaub.Txoj kev tseem ceeb ntawm impurities yog siv dej ntxuav los yog alkali ntxuav.

2. Cov khoom xyaw: Ntxiv ib qho nyiaj ntawm quartz xuab zeb thaum kneading, thiab muab cov khoom sib xyaw rau hauv cov khoom siv kneading.

3. Kneading: Muab cov khoom sib xyaw ua ke rau hauv nruab nrab ntawm graphite extruder, thiab tom qab ntawd knead thiab extrude cov ntaub ntawv raw kneaded los tsim lawv hauv graphite pwm.

4. Roasting: Hlawv cov khoom sib xyaw nrog charcoal rau hauv cov hluav taws kub kub lossis cov khoom siv hluav taws xob xws li carbon dub thiab charcoal hmoov, thiab tom qab ntawd nkag mus rau cov txheej txheem tom ntej.

5. Kev ua tiav: Tom qab pwm tsim, nws yuav tsum tau txiav, welded, polished thiab lwm yam txheej txheem.

6. Ntim: Moulds yuav tsum tau kuaj xyuas (nrog rau kev huv thiab seb puas muaj kev puas tsuaj thiab khawb, thiab lwm yam) thiab muab faib ua ke ua ntej lawv tuaj yeem khaws cia rau hauv lub warehouse.

Lub luag haujlwm ntawm cov txheej txheem carbonization yog: los tiv thaiv tus nqi ntawm oxidation ntawm qhov kub thiab txias, kom ntseeg tau tias cov hlau hauv cov slag yuav tsis volatilize;kom tswj tau cov tshuaj tiv thaiv carbothermal hauv lub xeev molten, kom ntseeg tau tias tus nqi yog smelted ntawm qhov zoo tshaj plaws kub thiab lub sij hawm.

Lub luag haujlwm tseem ceeb ntawm hluav taws xob arc rauv yog ua kom paub qhov hluav taws xob arc rau hauv tus nqi kom yaj cov khoom siv carbon hlau rau hauv cov hlau alloy.Cov khoom siv hluav taws xob ntawm hluav taws xob arc rauv feem ntau yog graphite electrode, anode thiab cathode graphite.

Carbonization rauv: charcoal yog hlawv nyob rau hauv lub cub tawg los tsim carbon thiab oxygen, thiab cov generated flue gas nkag mus rau hauv lub molten pas dej ua ke tom qab txias, thiab molten hlau yog tawm sab nraud tib lub sij hawm.

Rotary Kiln: Lub qhov txo qis yog siv rau hauv cov txheej txheem smelting rau smelting hlau lossis alloys.

Quote Now

Quote Now