Luv luv qhia txog graphite electrode

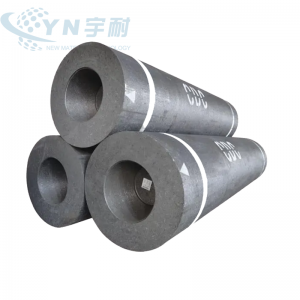

Graphite electrode hais txog roj av coke, pitch coke li aggregate, thee tar pitch li binder, thiab nws yog ib hom resistant electrode ua los ntawm calcination ntawm raw cov ntaub ntawv, crushing thiab sib tsoo, batching, kneading, molding, roasting, impregnation, graphitization thiab mechanical. tshuab.Cov khoom kub kub graphite conductive yog hu ua graphite electrode (hu ua graphite electrode)

Graphite electrode classification

(1) Ordinary hwj chim graphite electrodes.Nws raug tso cai siv graphite electrodes nrog qhov ceev tam sim no qis dua 17A / cm2, uas yog siv rau hauv cov hluav taws xob hluav taws xob zoo tib yam rau steelmaking, silicon smelting, daj phosphorus smelting, thiab lwm yam.

(2) Anti-oxidation coated graphite electrode.Cov graphite electrode coated nrog cov txheej txheem tiv thaiv oxidation ua cov txheej txheem tiv thaiv uas yog ob qho tib si conductive thiab resistant rau high-kub oxidation, txo electrode noj thaum steelmaking.

(3) High-power graphite electrodes.Graphite electrodes nrog qhov ceev tam sim no ntawm 18-25A / cm2 raug tso cai, thiab feem ntau yog siv rau hauv cov hluav taws xob hluav taws xob hluav taws xob rau hluav taws xob rau steelmaking.

(4) Ultra-siab zog graphite electrodes.Graphite electrodes nrog qhov ceev tam sim no ntau dua 25A / cm2 tau tso cai.Feem ntau siv nyob rau hauv ultra-siab zog steelmaking hluav taws xob arc rauv

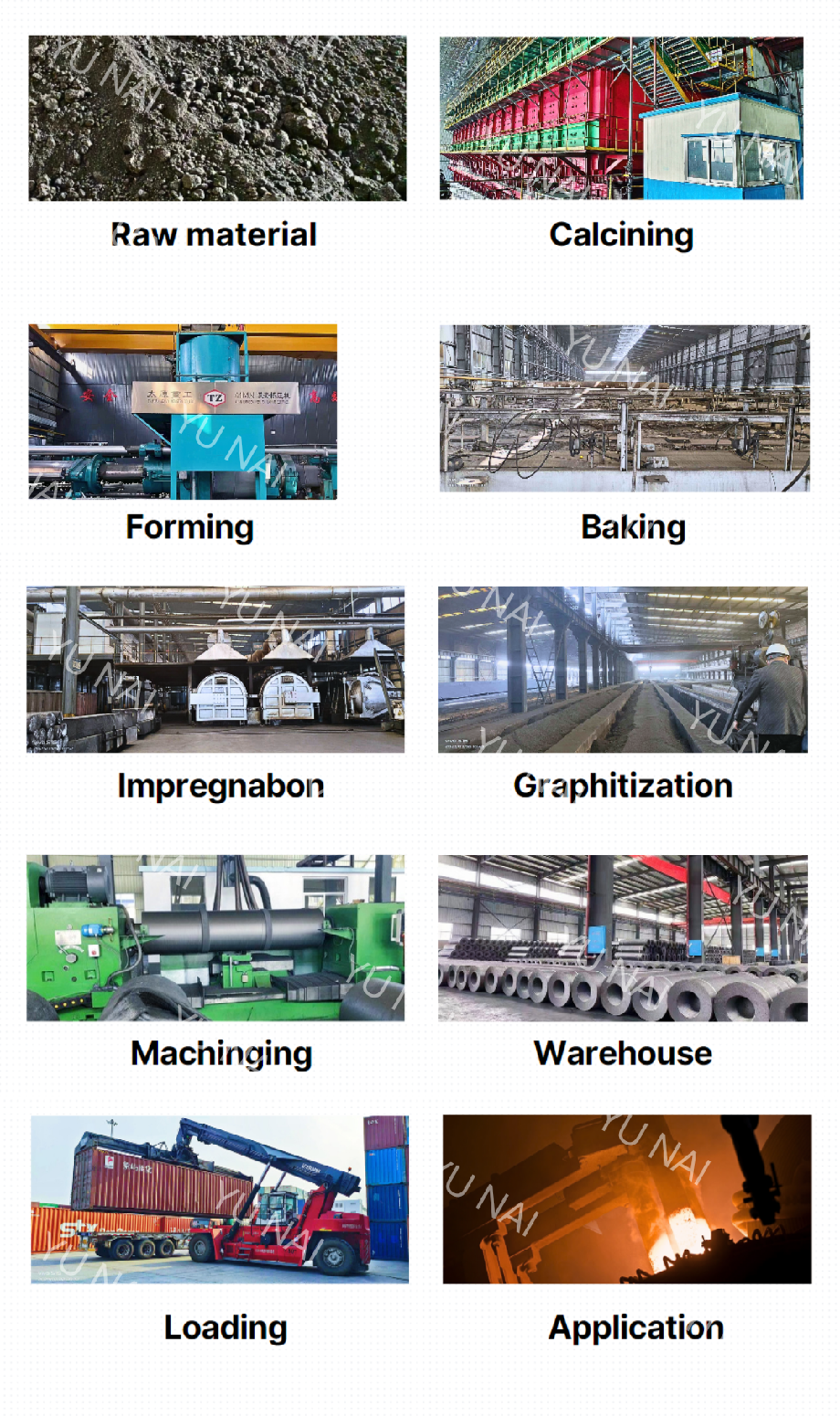

Kev tsim cov txheej txheem ntawm graphite electrode

Cov yam ntxwv ntawm graphite electrode

1. Muaj hluav taws xob thiab thermal conductivity;

2. High thermal vibration kuj thiab tshuaj stability;

3. Lubricity zoo thiab ruaj khov;

4, Yooj yim rau txheej txheem, tshem tawm cov hlau siab thiab qis graphite lossduring EDM (hluav taws xob hluav taws xob)

5. Qhov hnyav ntawm graphite yog 1/5 ntawm tooj liab, thiab graphite hnyav 1/5 qhov hnyav ntawm tooj liab hauv tib lub ntim.Qhov loj electrode ua los ntawm tooj liab yog hnyav dhau, uas yog qhov tsis zoo rau qhov tseeb ntawm EDM tshuab cuab tam spindle thaum lub sij hawm ntev hluav taws xob.Ntawm qhov tsis sib xws, graphite muaj kev nyab xeeb heev los daws.

6, Graphite muaj kev ua haujlwm siab uas yog 3-5 zaug sai dua li cov hlau zoo tib yam.Ntxiv mus, xaiv cov cuab yeej hardness thiab graphite tuaj yeem txo qhov hnav thiab tearof cutter thiab electrode.

Kev ceev faj rau kev siv graphite electrode

1.Thaum siv lossis khaws cov khoom siv electrode, cov neeg siv yuav tsum nco ntsoov kom tsis txhob muaj plua plav ya raws, muaj kuab paug.

thiab kev sib tsoo.

2.Thaum cov electrodes nqa los ntawm forklift tsheb, lawv qhov sib npaug yuav tsum tau khaws cia kom tiv thaiv

plam thiab tawg.Kev sib tsoo thiab overload raug txwv.

3.Cov electrodes yuav tsum muab cia rau hauv qhov chaw huv si thiab qhuav.Thaum khaws cia rau hauv qhov chaw qhib cua,

lawv yuav tsum tau them nrog tarpaulins.

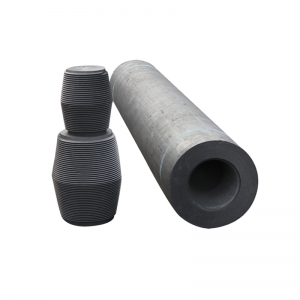

4.Thaum txuas cov electrodes, cov neeg siv ua ntej yuav tsum tau siv cov cua compressed los ntxuav cov xov ntawm electrode, ces ua tib zoo tig qhov sib cuag mus rau hauv ib qho kawg ntawm cov electrode thiab ntsia hlau.

electrode hoist mus rau lwm qhov kawg.Qhov kev sib tsoo nrog cov xov tsis tso cai.

5.Thaum ntaus lub electrode, cov neeg siv yuav tsum siv lub rotatable nuv nrog ib tug mos mos ncoo rau hauv qab ntawm lub txiv mis electrode los tiv thaiv kev puas tsuaj ntawm xov.

6.Ua ntej txuas cov elecrodes, cov neeg siv yuav tsum ntxuav lub qhov nrog compressed cua.

7.Siv ib tug elastic nuv hoist nqa lub electrode mus rau lub cub tawg, ces nrhiav qhov chaw thiab txav lub electrode mus maj mam.

8.Thaum lub tshuab hluav taws xob sab saud qis dua 20-30mm deb ntawm cov hluav taws xob qis, cov neeg siv yuav tsum siv cov cua compressed los ntxuav qhov sib txuas ntawm cov electrode.

9.Siv tshwj xeeb torque spanet kom nruj cov electrode raws li cov lus qhia, thiab siv

mechanical, hydraulic ntawm cov cuab yeej cua siab kom ceev cov electrode mus rau lub zog ruaj khov.

10.Lub electrode tuav yuav tsum tau clamped nyob rau hauv ob qho tib si sov sov kab

nruab nrab ntawm tus tuav thiab lub electrode yuav tsum huv si tsis tu ncua kom muaj kev sib cuag zoo nrog

cov electrode, thiab cov dej txias ntawm lub tuav yuav tsum raug txwv tsis pub tawm.

11.Npo rau saum cov electrode kom tsis txhob oxidation thiab hmoov av.

12. Txhawm rau kom tsis txhob tawg ntawm electrodes, cov neeg siv yuav tsum tsis txhob tso cov thaiv thaiv hauv qhov

rauv.Kev ua haujlwm tam sim no ntawm cov electrode yuav tsum tau sib haum rau kev tso cai ua haujlwm

tam sim no nyob rau hauv phau ntawv.

13. Kom tsis txhob electrode breakage, tso tej khoom nyob rau hauv qis qis thiab me me nyob rau hauv sab sauv.

Quote Now

Quote Now