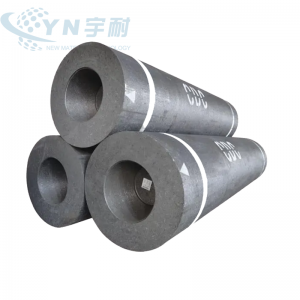

ultra siab zog graphite electrode

Kev siv thiab cov khoom ntawm graphite electrodes:

1. Siv nyob rau hauv hluav taws xob arc steelmaking rauv

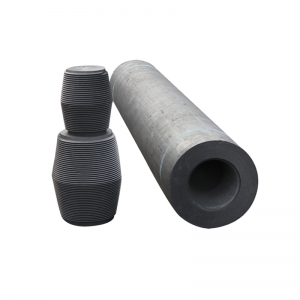

Graphite electrodes feem ntau yog siv nyob rau hauv hluav taws xob rauv steelmaking.Hluav taws xob rauv steelmaking yog siv graphite electrodes los qhia tam sim no rau hauv qhov cub.Lub zog tam sim no dhau los ntawm cov pa roj ntawm qhov qis kawg ntawm cov electrodes los tsim cov pa tawm arc, thiab cov cua sov tsim los ntawm arc yog siv rau smelting.Raws li lub peev xwm ntawm lub cub hluav taws xob, graphite electrodes nrog txawv diameters yog siv.Txhawm rau ua kom cov electrodes siv tsis tu ncua, cov electrodes txuas nrog electrode threaded pob qij txha.Graphite electrodes rau steelmaking account txog li 70-80% ntawm tag nrho cov nyiaj ntawm graphite electrodes.

2. Siv nyob rau hauv submerged tshav kub hluav taws xob rauv

Graphite electrode submerged thermal hluav taws xob rauv yog tsuas yog siv los tsim ferroalloy, ntshiab silicon, daj phosphorus, matte thiab calcium carbide, thiab lwm yam. Nws yog characterized nyob rau hauv hais tias lub qis ib feem ntawm cov conductive electrode yog faus rau hauv tus nqi, yog li ntxiv rau lub tshav kub. generated los ntawm lub arc nruab nrab ntawm cov hluav taws xob phaj thiab tus nqi, lub tshav kub tam sim no kuj generated los ntawm cov tsis kam ntawm tus nqi thaum nws dhau los ntawm tus nqi.Txhua tuj ntawm silicon yuav tsum haus txog 150kg ntawm graphite electrodes, thiab txhua tuj daj phosphorus yuav tsum tau noj li 40kg ntawm graphite electrodes.

3. Siv nyob rau hauv lub qhov cub tsis kam

Graphitization furnaces rau zus tau tej cov khoom graphite, melting furnaces rau melting iav, thiab hluav taws xob rauv rau zus tau tej cov silicon carbide yog tag nrho cov kuj furnaces.Cov ntaub ntawv nyob rau hauv lub cub tawg yog ob qho tib si cua sov resistors thiab cov khoom yuav tsum tau rhuab.Feem ntau, graphite electrodes rau conduction yog muab tso rau hauv lub burner phab ntsa ntawm qhov kawg ntawm lub hearth, thiaj li hais tias cov conduction electrodes tsis tas li noj.

4. Rau kev ua haujlwm

Ib tug loj tus naj npawb ntawm graphite electrode blanks kuj siv los ua ntau yam zoo li cov khoom xws li crucibles, graphite nkoj, kub pressing pwm thiab cua sov ntsiab ntawm lub tshuab nqus tsev hluav taws xob furnaces.Nws yuav tsum raug sau tseg tias muaj peb hom khoom siv hluavtaws rau cov khoom siv graphite ntawm qhov kub thiab txias, suav nrog graphite electrodes, graphite pwm thiab graphite crucibles.Graphite nyob rau hauv peb cov ntaub ntawv no yog nquag oxidative combustion tshwm sim nyob rau hauv high kub, uas ua rau ib tug carbon txheej nyob rau saum npoo ntawm cov khoom.Ntxiv porosity thiab xoob qauv cuam tshuam rau lub neej kev pab cuam.

Graphite electrodes feem ntau yog ua los ntawm roj av coke thiab rab koob coke, thiab thee tar pitch yog siv los ua cov ntawv khi.Lawv yog tsim los ntawm calcination, batching, kneading, nias, roasting, graphitization, thiab machining.Lawv tso hluav taws xob hluav taws xob nyob rau hauv daim ntawv ntawm arcs hauv hluav taws xob arc rauv.Cov conductors rau cua sov thiab melting tus nqi tuaj yeem muab faib ua lub zog zoo tib yam graphite electrodes, siab zog graphite electrodes thiab ultra-siab zog graphite electrodes raws li lawv cov ntsuas zoo.

Quote Now

Quote Now